What is CNC Workholding?

- Post author:FullGrip

- Post published:May 12, 2025

- Post category:Product Overview

The Foundation of Accuracy, Efficiency, and Growth in Modern Machining

In the world of CNC machining, precision isn’t just desirable… it’s non-negotiable. But behind every tight tolerance, smooth finish, and repeatable part lies an unsung hero: workholding.

Whether you’re running a 3-axis CNC machine or a 5-axis machining centre, how you hold your workpiece determines everything from accuracy, efficiency, repeatability, and ultimately, profitability.

Let’s break down what CNC workholding really is, how it evolves with machine capability, and why it’s the key to unlocking shop-floor efficiency.

From 3-Axis to 5-Axis: How CNC Workholding Evolves with the Machine

Every CNC machine, from entry-level 3-axis mills to full 5-axis machining centres, has one goal: to remove material precisely and efficiently. But as you add more axes, your approach to CNC workholding must evolve to match the machine’s complexity and potential.

3-Axis CNC Machines

The backbone of most machine shops.

3-axis CNC machines move in the X, Y, and Z directions. They’re straightforward, reliable, and ideal for general-purpose machining. These machines are the go-to for:

- Flat or prismatic parts

- Basic pocketing, contouring, and drilling operations

- Prototypes, jigs, and low-volume production runs

Because the cutting tool can only approach from one direction, each side of the part requires its own setup. That means:

- Re-clamping between operations

- Re-zeroing after every change

- A higher risk of stack-up error

Workholding here is often simple – vices, fixture plates, and mechanical clamps. For many shops, 3-axis machines are where the journey starts – they build skill, process control, and confidence. But for shops looking to reduce setup time and increase throughput, the next logical step is 4-axis machining.

4-Axis CNC Machines

Introducing rotation and flexibility.

Add a rotary axis (usually the A or B axis) to a 3-axis mill, and you open up an entirely new world of efficiency. 4th axis workholding allows the part to be rotated or indexed, giving access to multiple sides without breaking setup.

Shops move to 4-axis systems when they need:

- Faster cycle times by machining multiple faces in one setup

- Improved precision through reduced re-clamping

- Consistent production runs of parts with radial or cylindrical features

Common applications include:

- Shafts, gears, and impellers

- Components with radial holes or slots

- Fixtures and housings with multiple faces

However, this flexibility introduces new challenges for workholding.

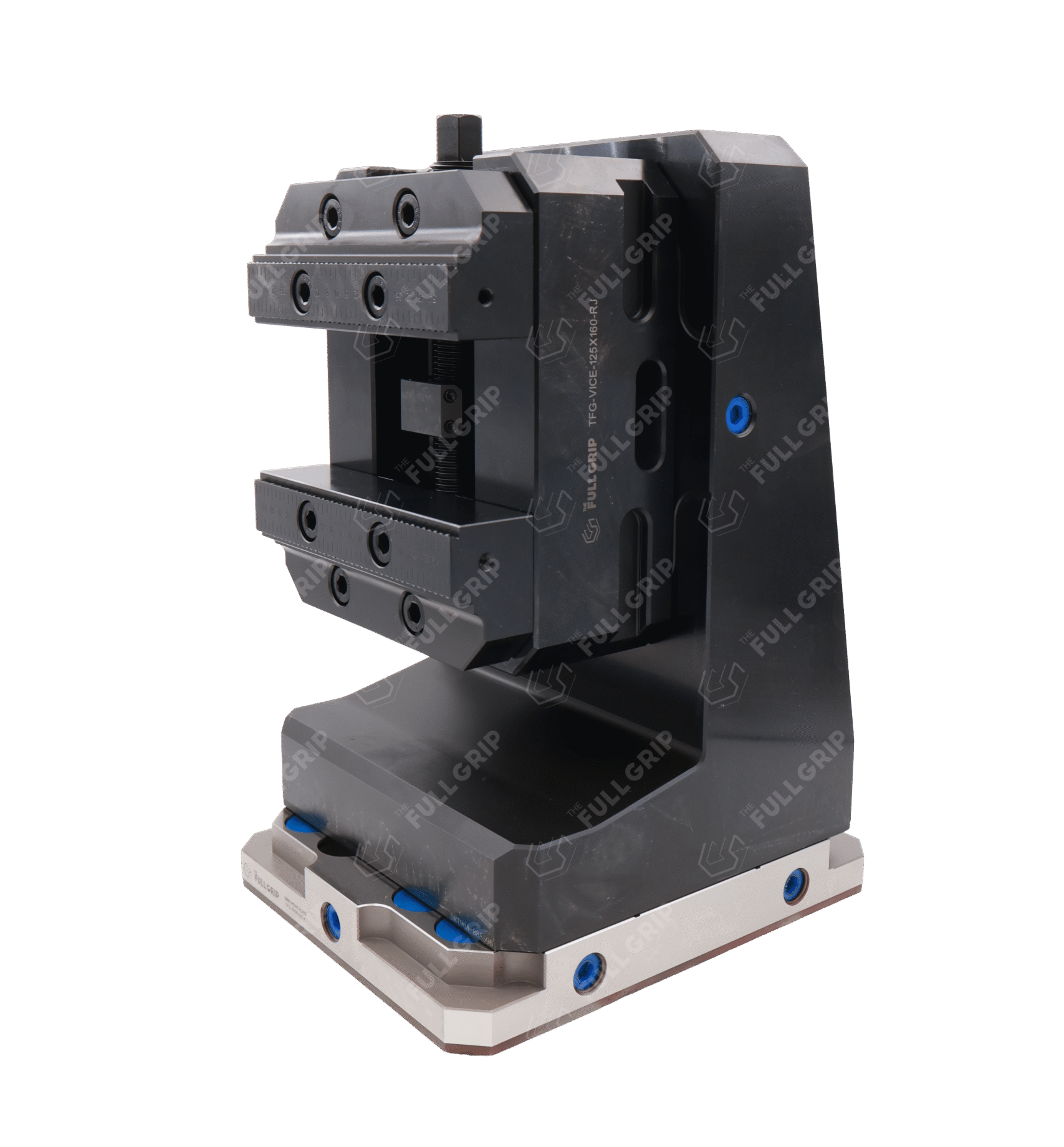

Rotating parts must stay balanced and concentric, meaning traditional vices or clamps aren’t enough. You’ll typically see self-centering vices, 4th-axis chucks, or rotary fixtures that maintain grip and alignment under rotation.

4-axis machining boosts productivity, but it’s not perfect. Undercuts and complex geometries still require re-orientation. That’s where risers and L-plates come in, helping achieve clearance and accessibility for multi-face work.

5-Axis CNC Machines

Where complexity meets capability.

Stepping into 5-axis CNC machining transforms your entire approach to manufacturing. By adding two rotary axes, the spindle or table can tilt and rotate, allowing the cutting tool to reach virtually any surface in one setup.

5-axis systems are made for:

- Aerospace and defence components

- Medical implants and surgical tools

- High-end automotive and motorsport parts

- Precision moulds and dies

These machines deliver exceptional efficiency, often taking a part from raw billet to finished component in a single operation. But that capability is only possible with the right 5-axis CNC workholding solutions.

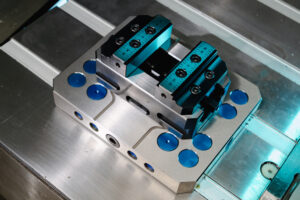

Here, rigidity, repeatability, and clearance are critical. You’ll often see:

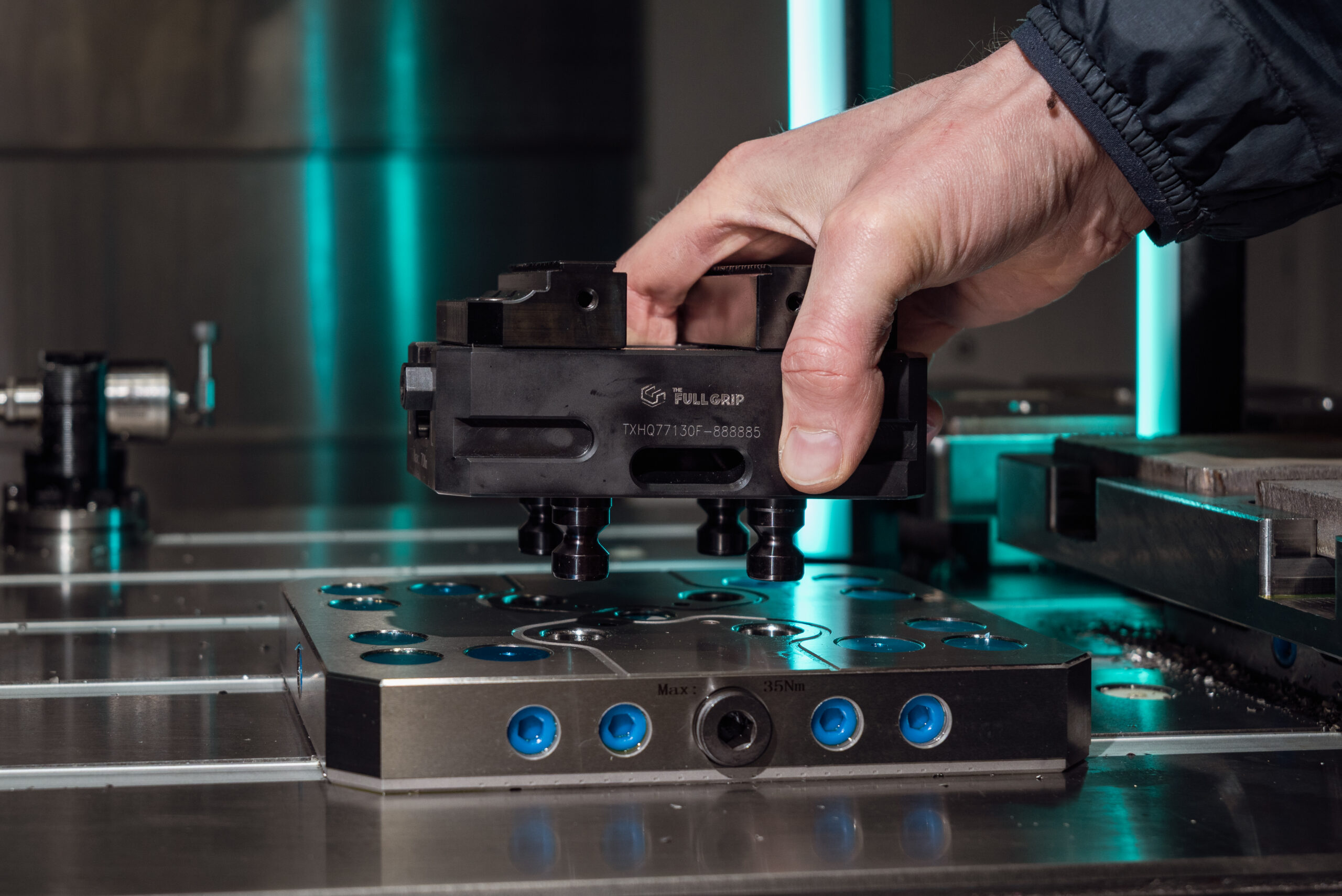

- Zero-point plates for ultra-fast fixture changes

- Self-centering vices designed for multi-angle machining

- Modular tombstones and risers that allow access to all faces

- Quick-change workholding that lets you swap parts or fixtures in seconds

The trade-off? More complexity in programming and setup, and higher investment. But for shops chasing true precision and scalability, 5-axis machining represents the pinnacle of efficiency and capability.

Efficiency Is Everything

In modern manufacturing, every minute counts. Setup time, tool changes, and re-clamping all eat into spindle uptime and ultimately, your bottom line.

That’s why CNC workholding solutions play such a critical role in driving efficiency. Tools like self-centering vices, zero-point plates, L-plates, tombstones, and risers don’t just hold parts… they create systems that flow.

Each component contributes to a faster, cleaner, and more repeatable process:

- Self-centering vices guarantee part alignment every time.

- Zero-point plates let you swap fixtures in seconds, not minutes.

- L-plates and tombstones enable multi-part or multi-face machining.

- Risers provide tool clearance and part accessibility.

Together, they form a quick-change workholding ecosystem that’s modular, repeatable, and designed to keep spindles cutting.

Efficiency Means Repeatability

The most productive shops in the world aren’t just fast, they’re consistent. When every fixture, plate, and vice locates precisely the same way every time, operators can transition from one operation to the next with minimal downtime.

That’s the power of repeatability. It reduces setup variation, maintains tolerance, and frees up machinists to focus on value-added work rather than manual adjustments.

In other words: efficient workholding is repeatable workholding.

Building Your Own Workholding Ecosystem

There’s no single workholding setup that fits every machine or every part. The right combination depends on your shop’s mix of work, machine type, and production goals.

But one thing stays constant: as your capability grows, so should your workholding.

Investing in modular, quick-change, and repeatable systems isn’t just about convenience – it’s about building an infrastructure that scales with your business.

At The Full Grip, that’s exactly what we’re here to help you do. Our range of CNC workholding solutions from self-centering vices to zero-point plates are built to fit together seamlessly, giving your shop the flexibility to adapt, scale, and keep cutting.

Ready to Take Your Workholding Further?

Discover how The Full Grip’s CNC workholding solutions can transform your machining efficiency.

Explore our range or get in touch – our team can help you build a setup that meets your production goals today and sets you up for growth tomorrow.