What is a Self-Centering Vice?

- Post author:Jenny Luistro

- Post published:January 2, 2026

- Post category:Product Overview

High-Precision Workholding for Faster CNC Setups

If you’ve spent any time around CNC machines, you know the setup is where time disappears.

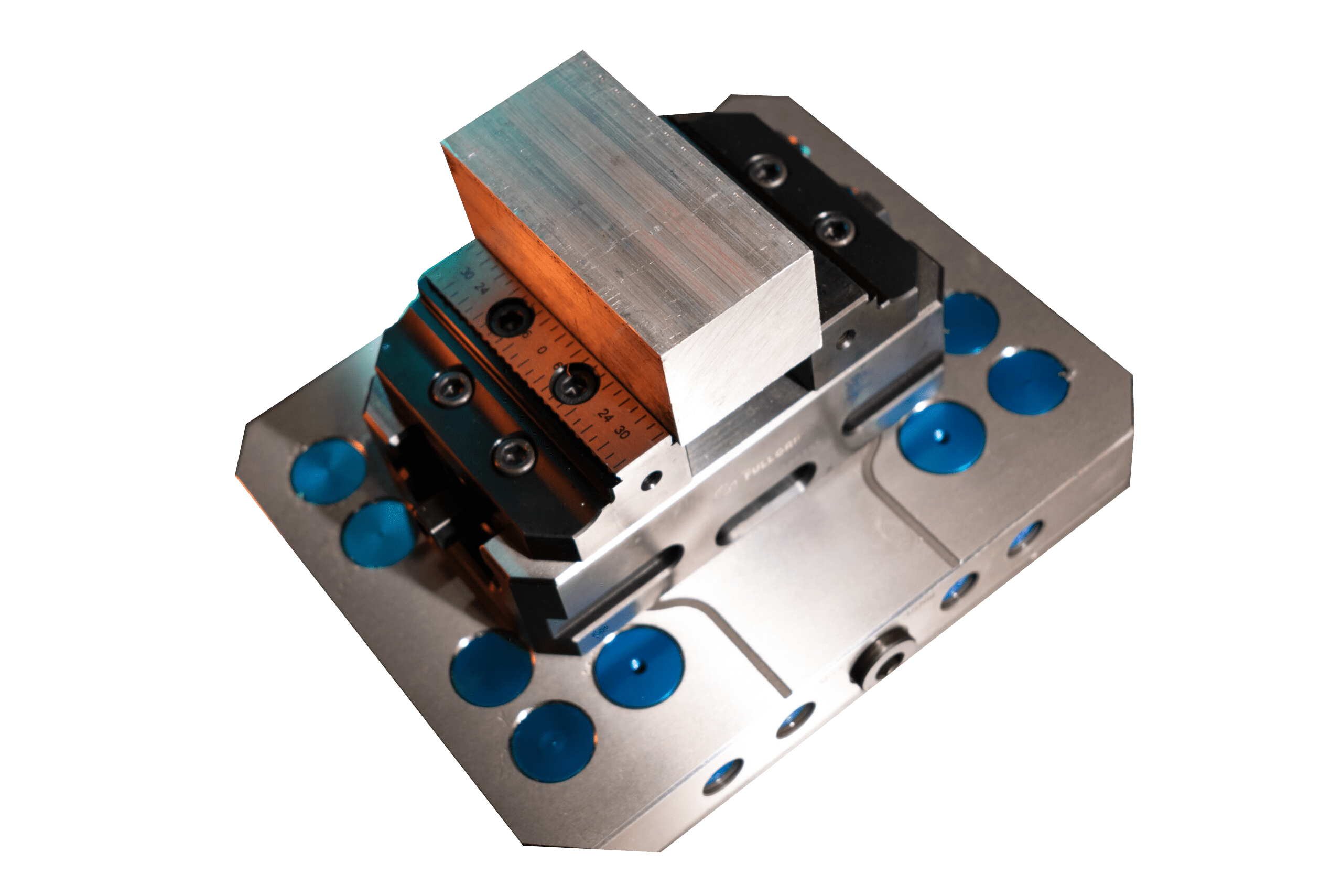

That’s where the self-centering vice comes in. A clever piece of workholding that’s changed the way machinists approach precision setups. At The Full Grip, we use them in our own shop every day, and once you understand how they work, it’s easy to see why.

What Is a Self-Centering Vice?

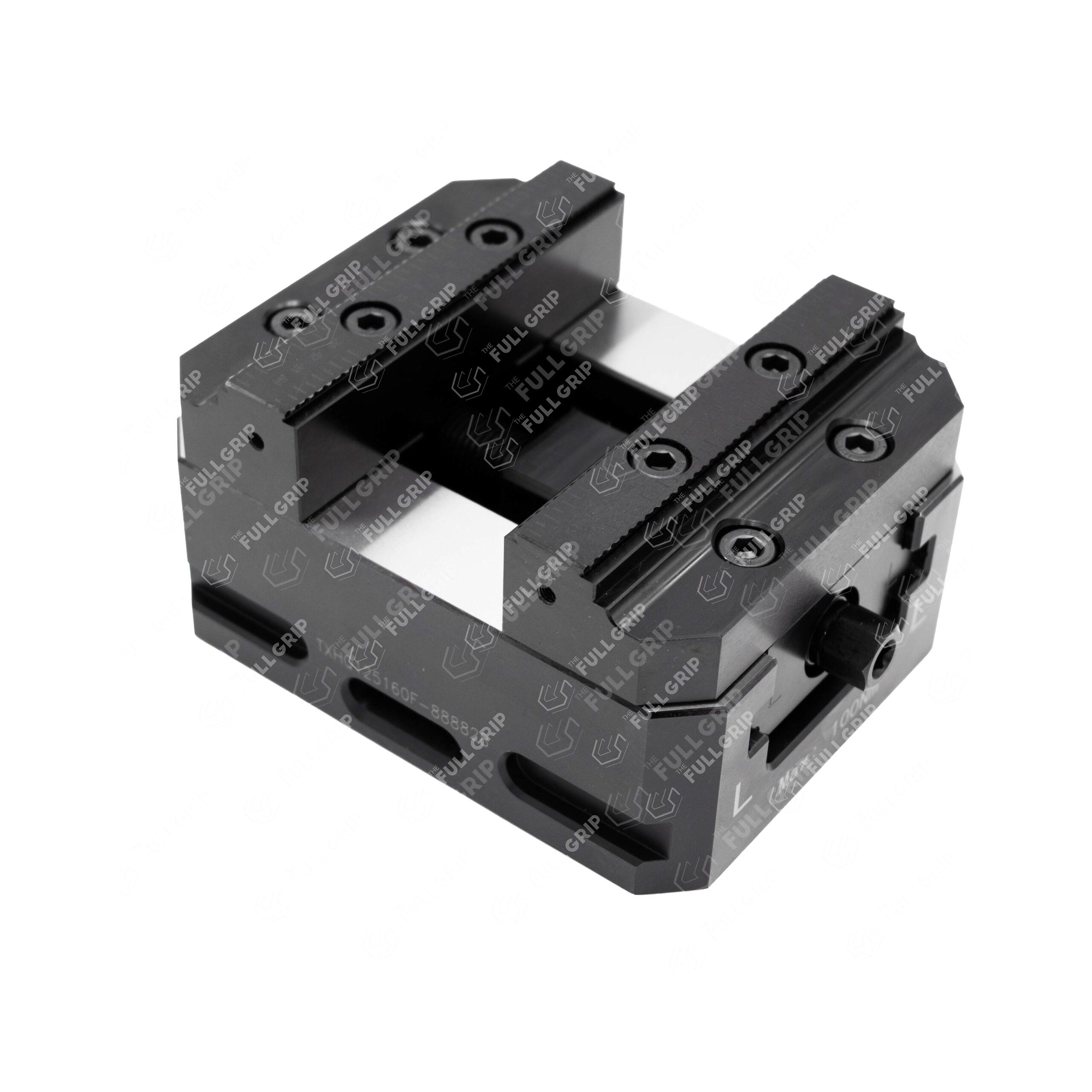

A self-centering vice is designed to automatically position your workpiece right in the middle – no measuring, no guesswork. Both jaws move together, closing in from each side to find the perfect centre. The result is repeatable accuracy every single time you clamp a part.

In simple terms: you drop your workpiece in, clamp down, and it’s automatically centred. For high-precision machining, that’s gold. It saves setup time, reduces the chance of human error, and keeps your parts consistent across multiple runs.

You’ll sometimes hear them called a self-centering milling vice or self-centering machine vice. Whatever you call it, the idea is the same: faster setups, more accurate positioning, and less fiddling around.

Why It Matters

In CNC machining, accuracy is only half the battle… repeatability is what makes or breaks your workflow. A precision self-centering vice ensures every part is clamped in exactly the same place every time you run the job. That means your offsets stay consistent, toolpaths line up perfectly, and you don’t lose minutes (or hours) re-zeroing between setups.

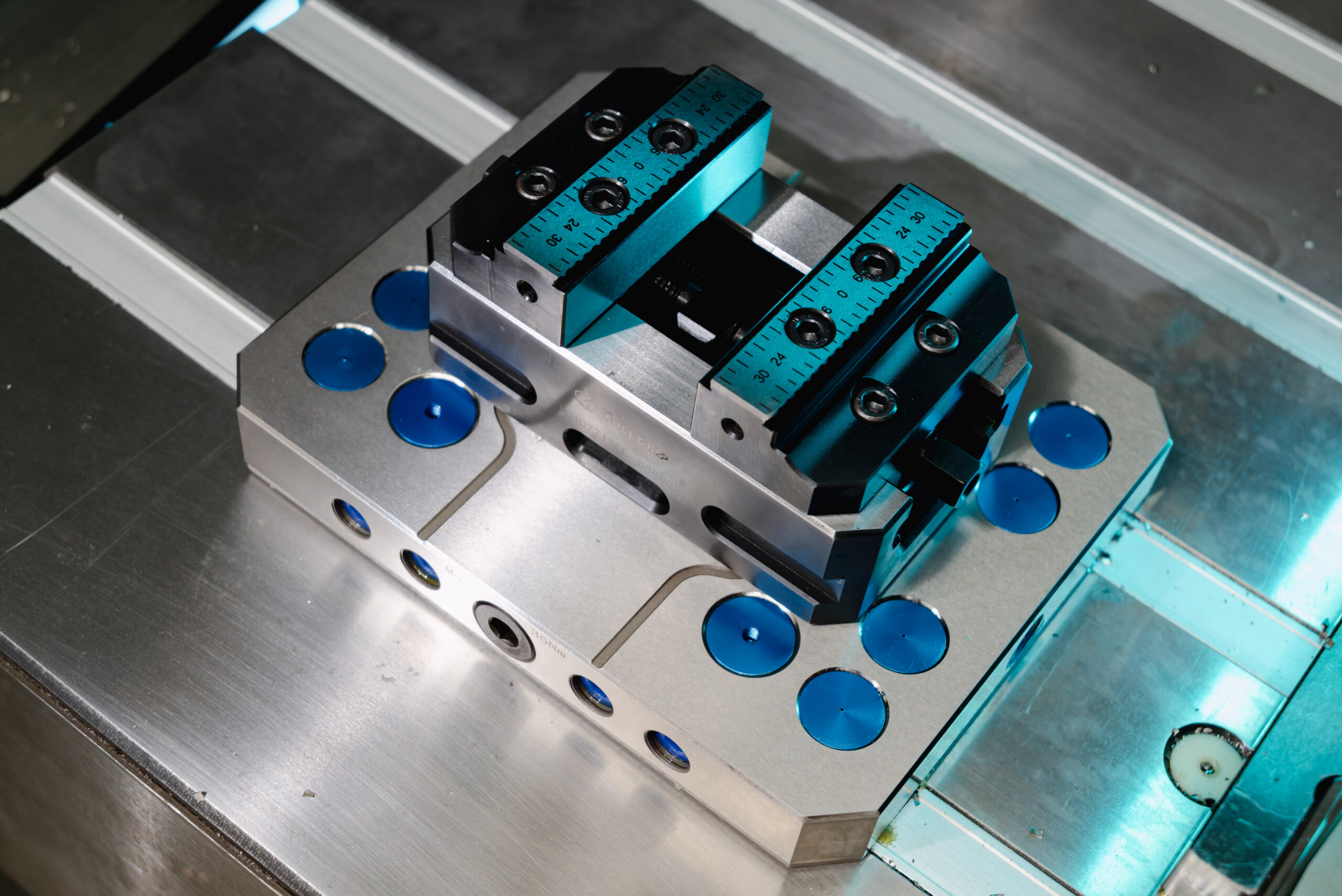

They’re also compact and low-profile, which makes them perfect for smaller CNC machines or when you need to fit multiple vices on a single table. Whether you’re machining small aluminium components, tool steel parts, or prototyping assemblies, having reliable, repeatable workholding makes the whole process smoother.

Clamping Range and Sizes

At The Full Grip, we’ve got two series of self-centering vices that cover just about every job size you’ll encounter – though the principles apply across the board.

125mm Wide Series – lengths from 130 to 310mm

These are perfect when you’re working with larger components or parts that need a stronger clamping force. Think structural brackets, fixtures, or tool steel parts that need deep milling cuts.

77mm Wide Series – lengths from 90 to 210mm

Ideal for smaller, more intricate parts where space on the table matters. Perfect for jobs like custom aluminium components, precision housings, or small batch production runs.

Both ranges give you the same benefits: quick setups, perfect centering, and a secure hold.

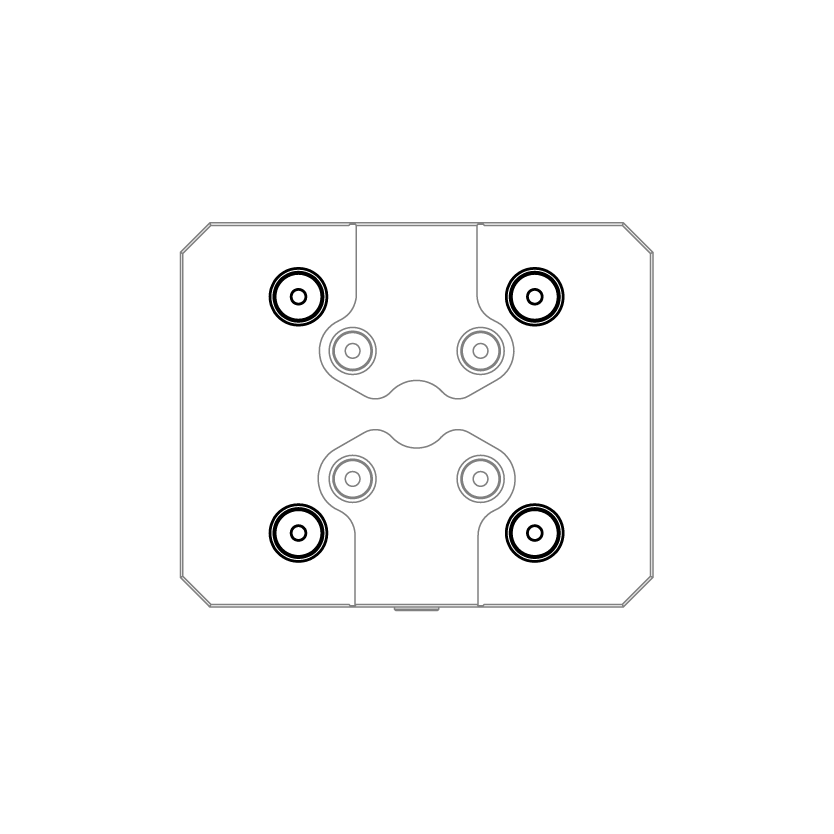

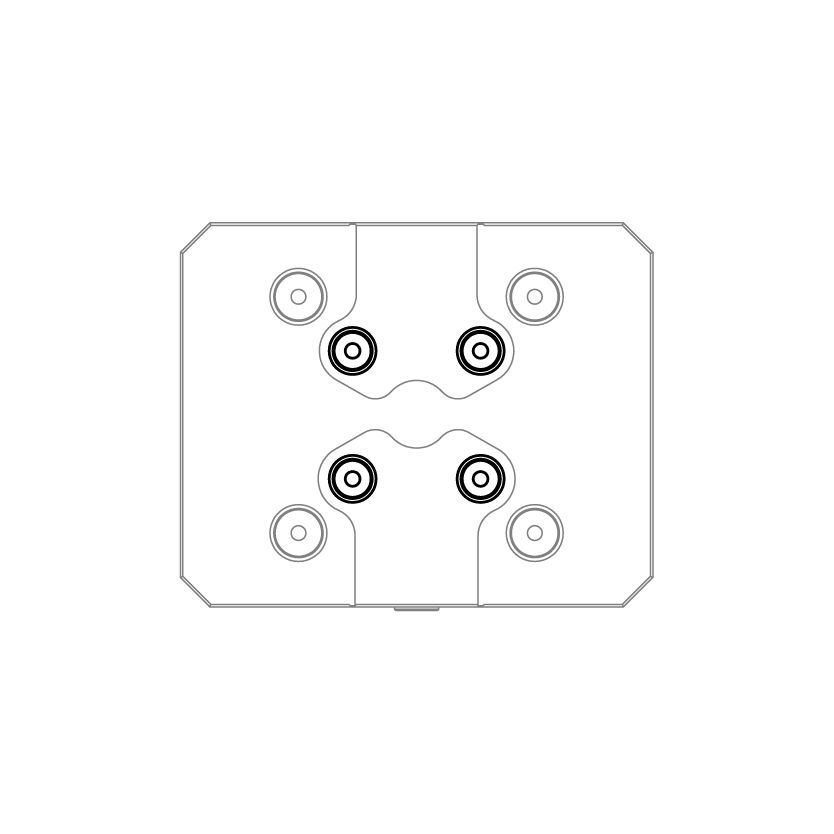

Hole Patterns: 96x96mm and 52x52mm

Our self-centering vices use industry-standard hole patterns:

96x96mm

52x52mm

This means they’re fully compatible with most modular workholding systems out there. You can drop them straight into your existing setup without needing adapters or custom plates. And if you’re running a zero-point system, even better, it’s just plug and play.

For machinists, this kind of flexibility is key. You can swap between brands or systems without losing alignment or wasting time on conversions.

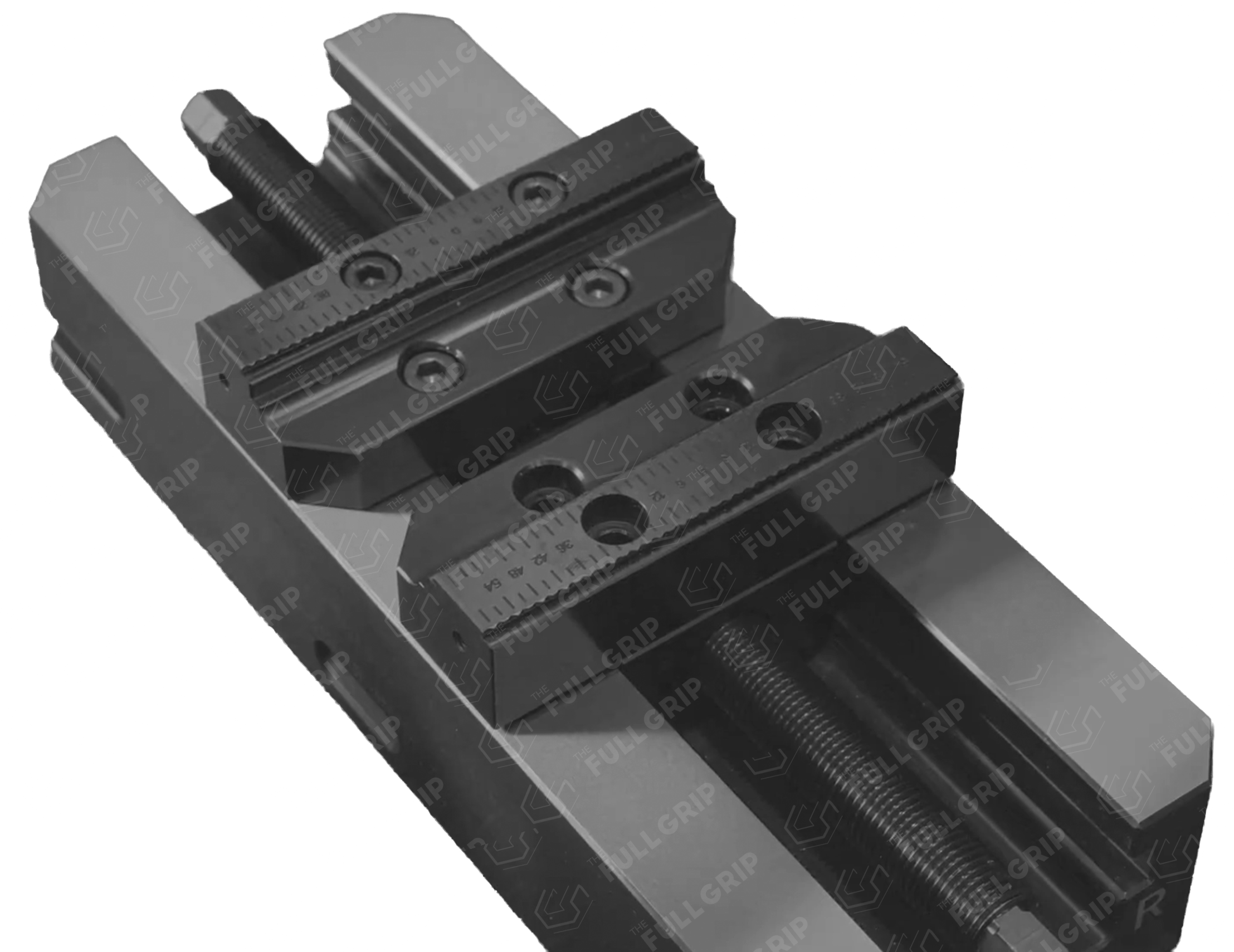

Serrated Teeth and Removable Jaws

Each vice features serrated teeth on the jaws to ensure a solid grip, even under heavy clamping forces. This keeps your workpiece stable during aggressive milling operations — no slippage, no vibration.

And when you need a different jaw profile, you can swap them out. The removable jaws make it easy to change between setups or replace worn ones without replacing the entire vice.

That’s cost-effective engineering — built to last, but flexible enough to adapt.

Clamping Tasks and Use Cases

Self-centering vices are more versatile than most people think. They can handle a range of clamping styles, depending on the type of work you’re doing.

Forward Clamping

This is your standard setup - both jaws close inwards to hold the workpiece.

Example: Holding square or rectangular billets for pocketing, profiling, or contour milling. Perfect for general-purpose CNC work.

Reverse Clamping

Flip the jaws around and the vice opens outward. This allows you to grip the internal sides of a part.

Example: When you’ve already machined the exterior of a housing or bracket and now need to machine the internal features, reverse clamping gives you full access.

Dovetail Clamping

Some machinists use dovetail jaws to secure parts via a small pre-machined dovetail at the base of the workpiece.

Example: Great for 5-axis setups where you need full tool clearance around the part, or when machining from multiple angles. It’s a small detail, but it’s what separates a good setup from a great one.

Precision and Durability Built In

Our self-centering vices are made from hardened tool steel, built to handle years of use under high clamping forces without flex or drift.

They hold internal tolerances of ≤ 0.01mm, giving you the repeatability needed for precision machining.

That’s the kind of accuracy that lets you trust your setup run after run — no remeasuring, no second-guessing.

And because they’re compact and low-profile, you can run multiple vices side by side on the same machine table, multiplying your productivity without sacrificing precision.

Final Thoughts

Whether you call it a self-centering vice, self-centring machine vice, or even a precision milling vise, the principle stays the same: hold smarter, not harder.

For machinists chasing accuracy and efficiency, it’s one of the most impactful upgrades you can make to your setup. Less time measuring. Less rework. More time cutting metal.

And that’s exactly what good workholding should do.