How Accurate Are Self-Centering Vices? Precision, Repeatability, and CNC Reality

- Post author:FullGrip

- Post published:January 9, 2026

- Post category:Product Overview

When machinists ask about self-centering vices, the question usually isn’t “What do they do?”

It’s “How accurate are they… really?”

It’s “How accurate are they… really?”

Accuracy in CNC machining isn’t just about hitting a dimension once. It’s about repeatability, consistency, and trusting your setup across multiple operations. This is where a well-designed self-centering vice earns its place on the machine table.

Let’s break it down properly.

What Is a Self-Centering Vice?

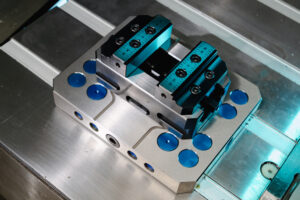

A self-centering vice is a precision workholding device where both jaws move simultaneously toward the centre as you clamp a part.

Unlike a traditional machine vice, where one jaw moves and the other stays fixed, a self-centering design ensures the workpiece is automatically aligned on the centreline of the vice every time. No shimming. No nudging. No tapping with a mallet and hoping for the best.

The result is faster setups and far more predictable positioning, especially when you’re running repeat jobs or multiple vices on the same table.

We break this topic down deeper here.

How Do Self-Centering Vices Work?

At the heart of a self-centering vice is a synchronised internal mechanism, usually a precision-ground screw or rack system, that drives both jaws evenly.

When you tighten the vice:

- Both jaws move inward at the same rate

- The part is pulled to the centre automatically

- Clamping force is distributed evenly across the workpiece

Because both jaws travel together, the centre point stays consistent even when you change part sizes.

This mechanical symmetry is the key to accuracy. There’s no sideways force pushing the part out of alignment, which is a common source of error in traditional vices.

How Accurate Are Self-Centering Vices?

Accuracy in self-centering vices is best described through repeatability, not just a single measurement.

A high-quality precision self-centering vice will typically offer:

- Repeatability within ≤ 0.01 mm

- Minimal jaw lift under clamping force

- No measurable drift across repeated clamp cycles

What that means in practice:

- You can remove a part, re-clamp it, and trust it will sit in the same position

- Multiple parts can be machined with consistent offsets

- Toolpaths remain reliable across batches

This level of repeatability is especially valuable for CNC machinists running:

- Small batch production

- Multi-vice setups

- Zero-point or palletised workflows

Accuracy isn’t just about tight tolerances… it’s about confidence in every setup.

Why Use a Self-Centering Vice?

Faster Setup Times

Because parts automatically centre themselves, setup becomes a quick, repeatable process. No edge finding every time. No manual alignment.

Better Consistency Across Jobs

When every part sits in the same position, offsets stay the same. That reduces setup errors and speeds up job changeovers.

Improved Accuracy Under Load

Quality self-centering vices are made from hardened tool steel and designed to resist flex. That matters when you’re taking heavier cuts or machining harder materials.

Compact, Space-Saving Design

Most self-centering vices are low-profile and compact, making it easier to run multiple vices on one table without sacrificing working envelope.

Ideal for Modern CNC Workflows

They integrate naturally with zero-point systems and modular fixturing, which is why they’re so common in high-efficiency CNC shops.

Accuracy Depends on Design, Not Just the Label

Not all self-centering vices are created equal.

Accuracy depends on:

- Internal tolerances of the drive mechanism

- Jaw guidance and surface finish

- Material hardness and heat treatment

- How well the vice resists deflection under clamping force

A well-built self-centering machine vice maintains its accuracy over time, even with repeated use. A poorly built one may centre well on day one and drift as wear sets in.

That’s why repeatability figures and build quality matter more than marketing claims.

The Bottom Line

So, how accurate are self-centering vices?

In a properly engineered system, accuracy and repeatability within ≤ 0.01 mm is not only achievable, it’s expected.

For CNC machinists who care about consistency, speed, and predictable results, a self-centering vice isn’t just a convenience. It’s a foundational tool that makes precision easier, not harder.

And once you’ve run one properly, it’s hard to go back.