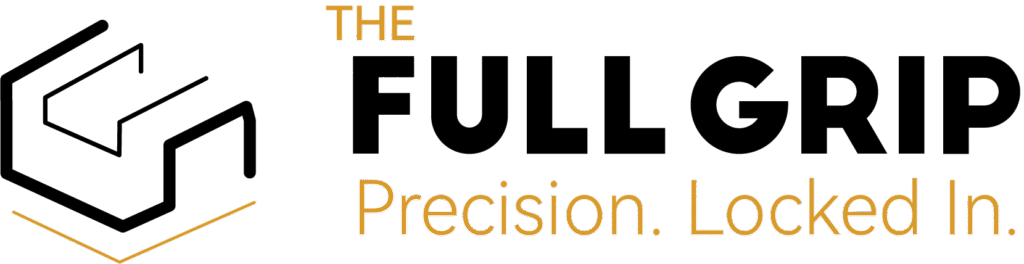

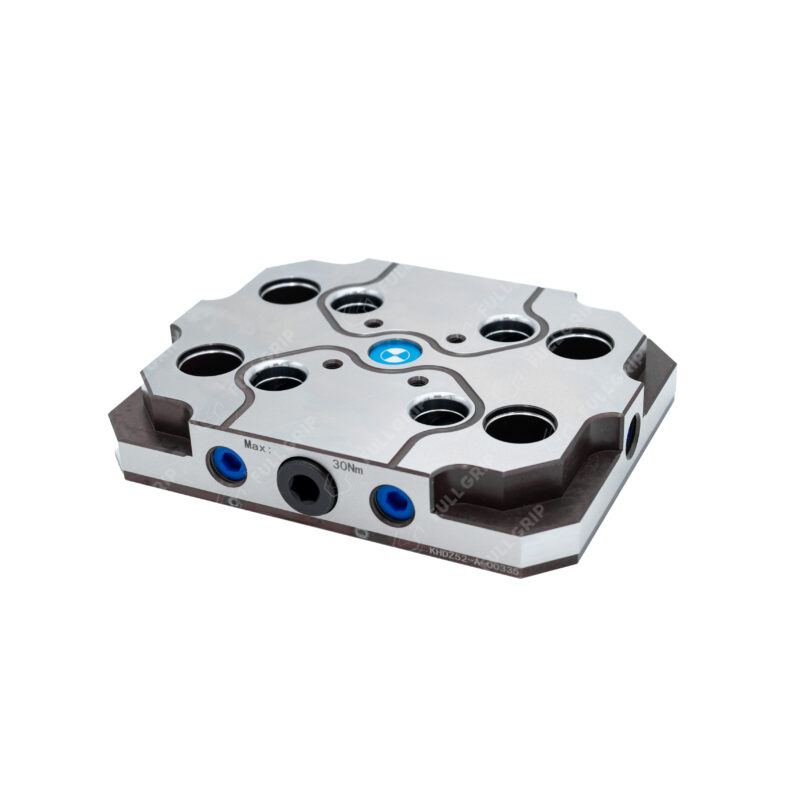

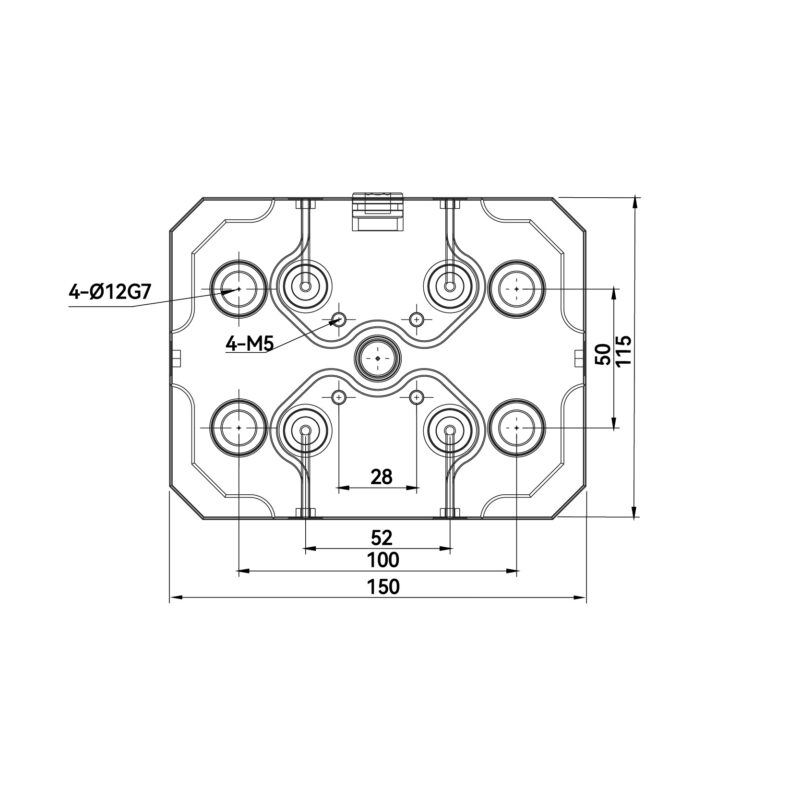

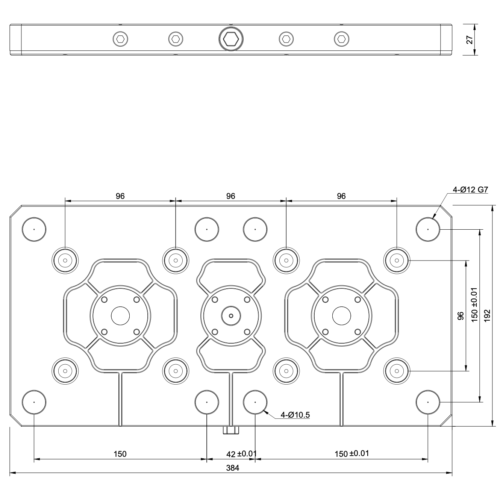

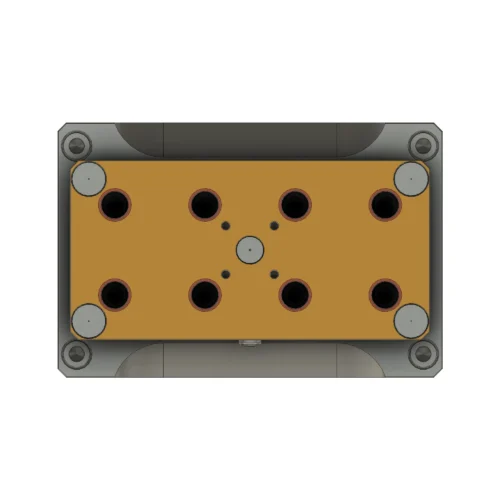

Zero-Point Plate – Rectangle – 150x116x27mm – Grid 52

$660.00 incl. GST

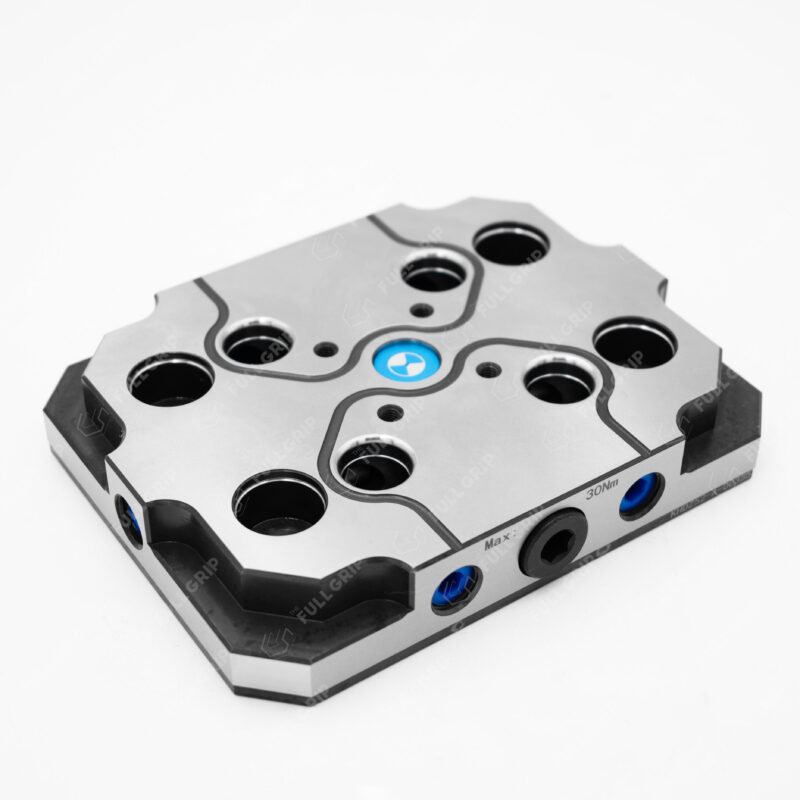

High-Precision Zero-Point Base Plate for CNC Machining

Dimensions

Weight

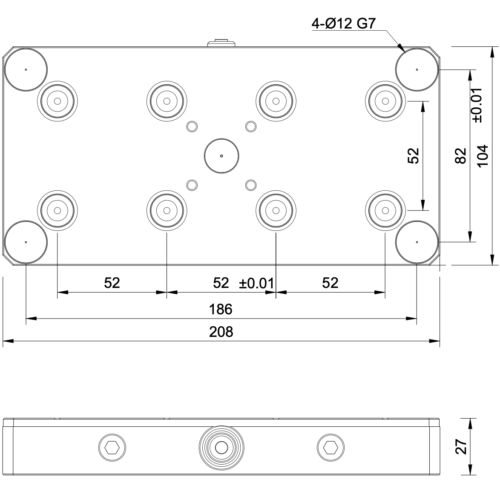

150×116×27 mm

2.9 kg

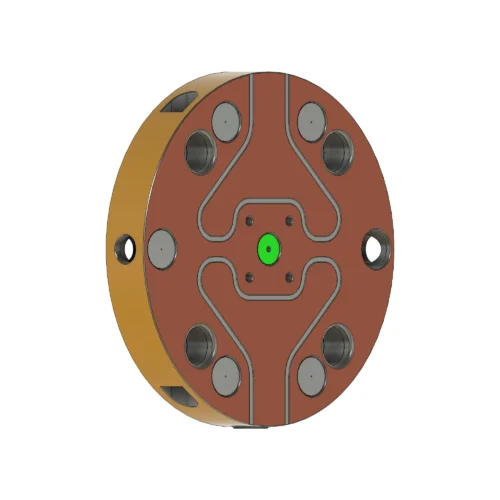

When repeatability, speed, and reliability matter, the TMC 52 Single Plate delivers. Engineered for precision and built from premium hardened tool steel, this zero-point base plate is a cornerstone of efficient CNC machining workflows. Whether you’re doing high-mix, low-volume production or just need a solid, repeatable base for your fixtures, the TMC 52 gets the job done with minimal fuss.

Designed to work seamlessly with 52 mm zero-point clamping systems, the TMC 52 Single Plate is compatible with a wide range of clamping studs and automation setups. It allows for lightning-fast fixture changes while maintaining sub-5-micron repeatability — keeping your spindles cutting and your team productive.

Description

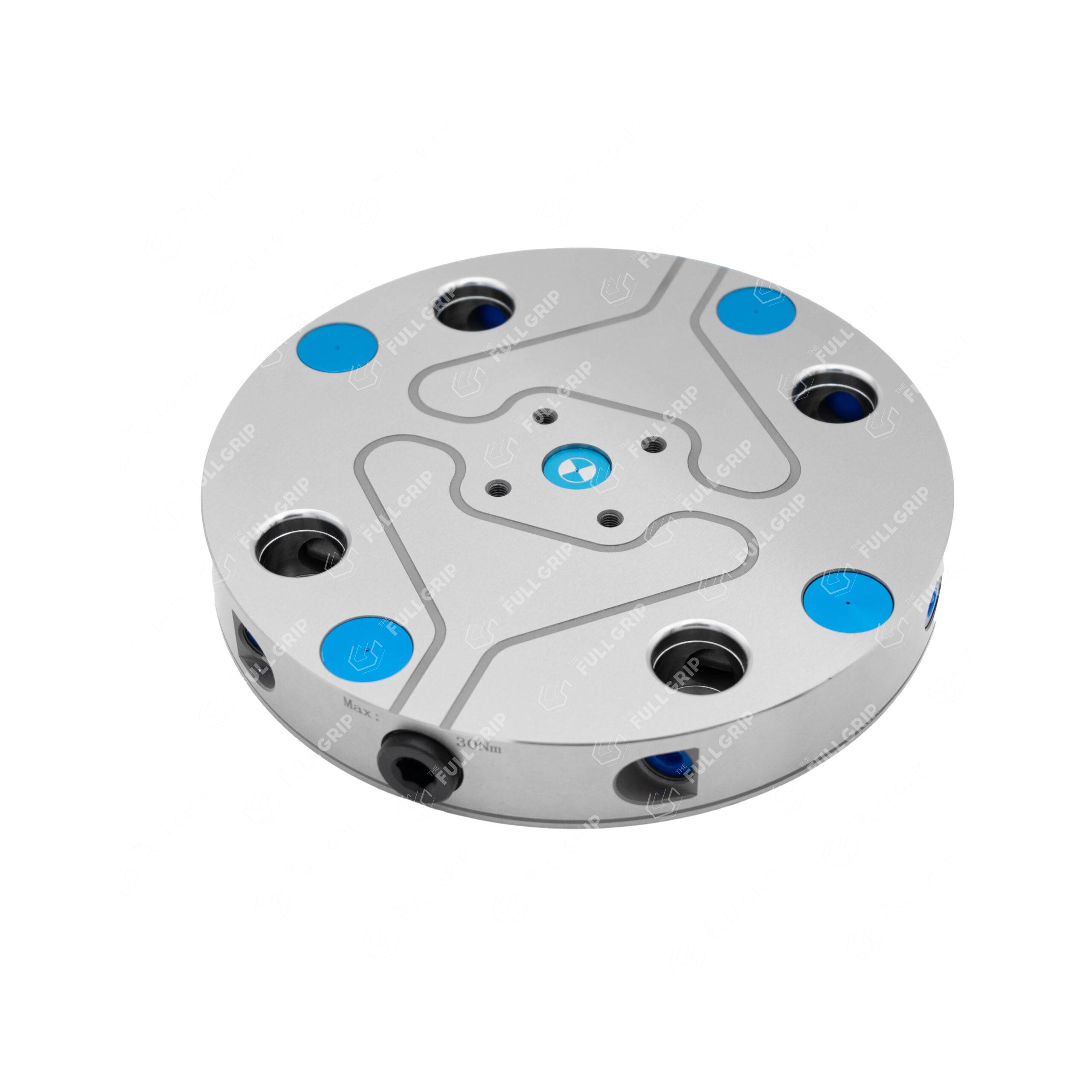

Product Highlights:

- Precision Repeatability:

≤ 0.005 mm positioning accuracy for consistent machining results across setups. - Robust Build Quality:

Manufactured from hardened tool steel, the plate resists wear and deformation under heavy loads and repeated clamping cycles. - Optimised Design for Fast Changes:

The single-station format allows easy integration into custom jigs or direct mounting on CNC tables. Perfect for both manual setups and automated pallet systems. - Standardised Interface:

Uses the 52 mm zero-point pitch, compatible with all major clamping studs and pull-down systems in the market. - Ready to Install:

Supplied with pre-drilled mounting holes and a precision-ground surface to reduce setup time and ensure maximum contact accuracy. - Versatile Application:

Ideal for vertical and horizontal machining centres, EDM setups, inspection fixtures, and more.

Additional information

| Weight | 2.9 kg |

|---|---|

| Dimensions | 15 × 11.6 × 2.7 cm |

| Material | |

| Grid System | |

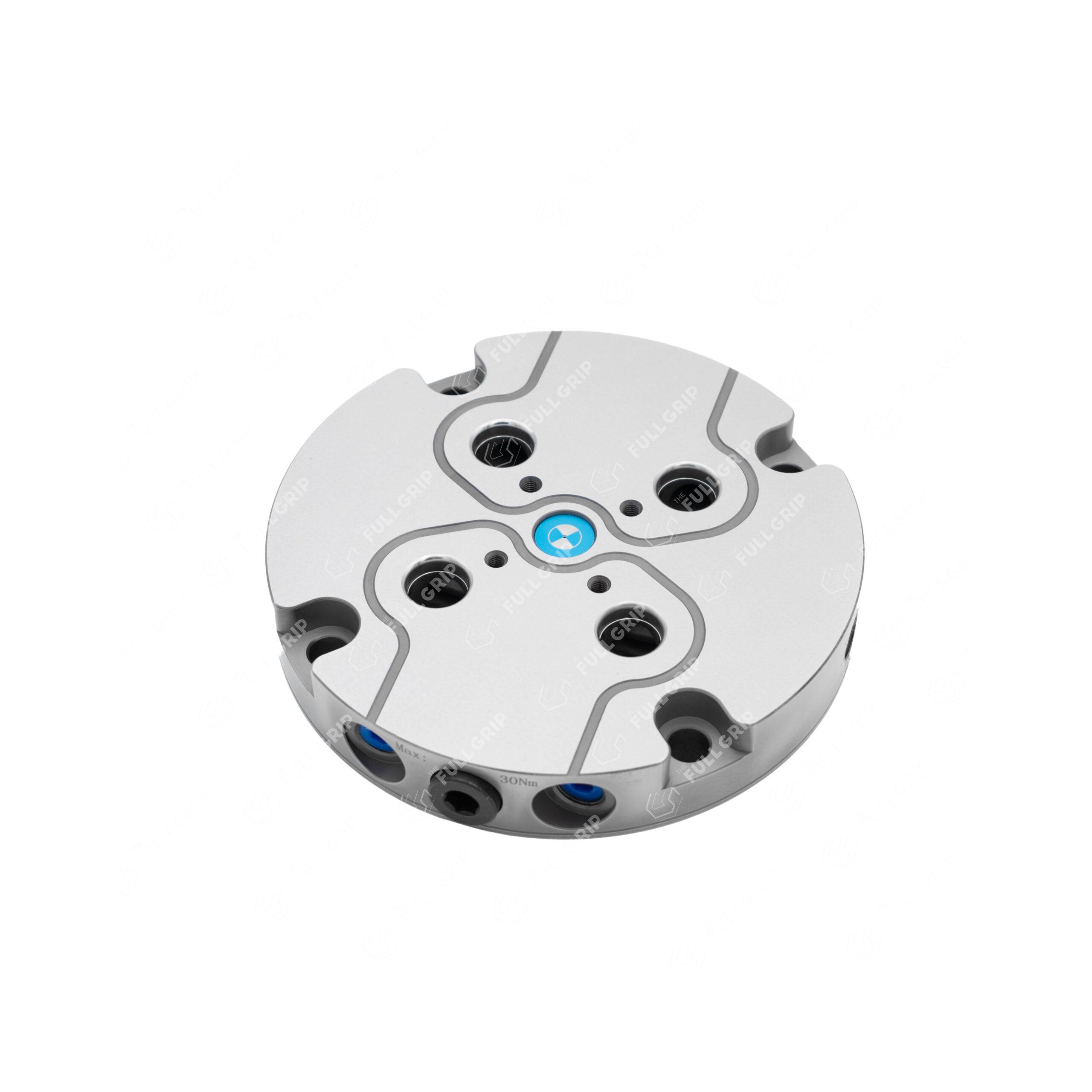

| Torque | 30Nm |

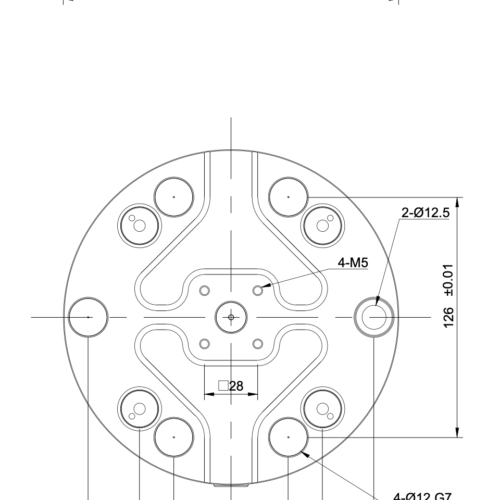

| Stud Pitch | Ø16/52mm |

| Locking Force | 18KN (4 Rivet) |

| Repeatability | ≤ 0.005 mm |

| Precision Locating Holes | 4 holes, Ø12G7 |

| T-Slot Spacing | 100mm, 50mm |