-

- Single Plates, System 96, Zero Point Plates

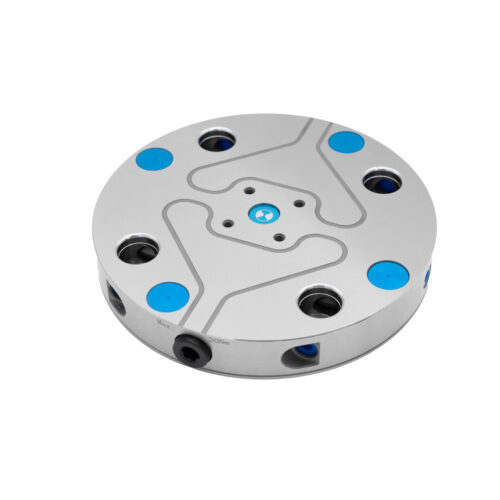

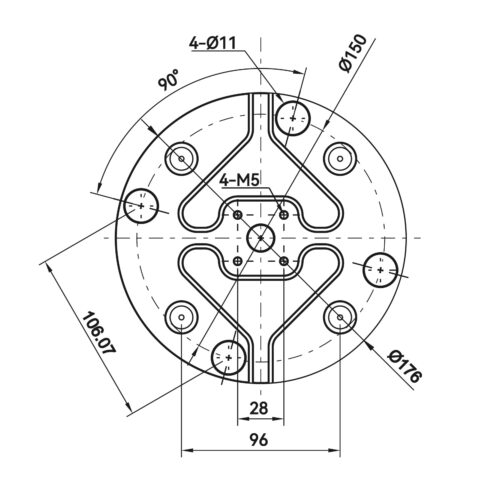

Zero-Point Plate – Round – Ø176x27mm – Grid 96

- $700.00 incl. GST

- Heavy-Duty Zero-Point Clamping Plate for Maximum Holding Power Dimensions Weight Ø176x27mm 4.5 kg Built for serious holding strength and unbeatable repeatability, The Full Grip – 96 Round Plate is a…

- Add to cart

-

- Combo Plates, Single Plates, Zero Point Plates

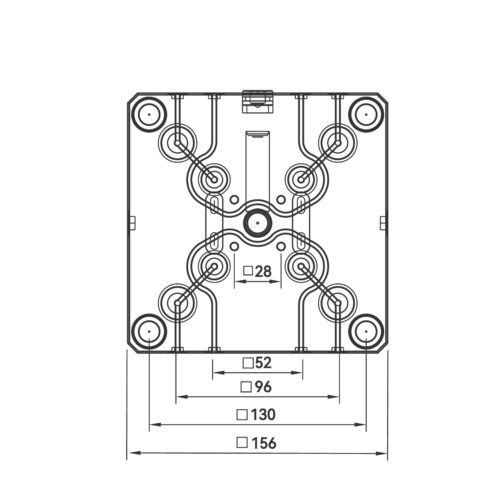

Zero-Point Combo Plate – 52 / 96 Grid – Square – 156x156x27mm

- $1,080.00 incl. GST

- Modular Zero-Point Base Plate for Mixed-System Machining Dimensions Weight 156×156x27 mm 4.3 kg The Full Grip – 52 / 96 Combi Plate / Square is the perfect all-rounder for workshops…

- Add to cart

Single Plates

Single Plates

Single Zero Point Plates for Precision, Simplicity, and Flexibility

The Full Grip’s single zero point plates are purpose-built for high-accuracy clamping in compact or dedicated setups. Designed for single-fixture applications, these plates come in round, square, and rectangular configurations to suit both 52 mm and 96 mm zero point grid systems.

Manufactured from high-quality martensitic tool steel (HRC 55–58), each plate delivers exceptional rigidity, repeatability, and wear resistance, making it ideal for demanding production and precision machining environments.

Available with pre-drilled mounting holes or as blank plates for custom machining, these single zero point workholding plates can be seamlessly integrated into machine tables, clamping towers, pallets, or CNC rotary tables.

Whether you’re setting up for 3-axis work or a complex 5-axis fixture, our single plates offer the modular precision needed to keep your spindle cutting and your setup time minimal.

How Single Zero Point Plates Differ from Combo Plates

While our Combo Zero Point Plates are designed for multi-fixture setups and batch production, single zero point plates focus on precision and dedicated part clamping. They’re perfect for smaller components, one-off parts, or applications where accuracy and simplicity take priority.

A single plate ensures minimal interference and maximum rigidity, providing a reliable mounting base that’s quick to install, align, and maintain. When paired with modular workholding systems like Self-Centering Vices, they create an efficient, repeatable, and compact setup that’s easy to reconfigure as jobs change.

Compatible with Standard 52 mm and 96 mm Systems

Our single zero point mounting plates are fully compatible with industry-standard 52 mm and 96 mm zero point systems, allowing seamless integration into your existing setup. Whether you’re upgrading from another brand or expanding your fixturing system, The Full Grip plates provide the versatility to mix and match components without modification.

Their modular design makes them compatible with leading workholding brands, so you can enjoy true flexibility across machines, fixtures, and operations.

Built from Hardened Martensitic Tool Steel (HRC 55–58)

Each zero point plate is precision-machined from martensitic tool steel, hardened to HRC 55–58 for outstanding durability, wear resistance, and longevity. This premium material choice ensures consistent performance even in high-load and high-repetition machining environments.

The hardened surface also maintains accuracy through repeated clamping cycles, guaranteeing that every setup remains stable and true.

Custom Bolt Options and Blank Plates

We understand that every workshop has unique mounting requirements. That’s why we offer both pre-drilled mounting plates and blank versions, allowing machinists to drill their own holes to fit specific table layouts.

Custom bolt options are also available, giving you flexibility to adapt your zero point system precisely to your machine’s geometry. Simply contact our team for a tailored configuration.

Round vs. Square and Rectangular Plates: Which Is Best for You?

Round zero point plates are perfect for rotary tables or applications that require smooth indexing and rotational symmetry. Their compact footprint and central clamping design make them ideal for dynamic setups or 4th/5th-axis machining.

Square and rectangular plates, on the other hand, offer greater surface area for mounting fixtures and are best suited for machine tables, pallets, or tombstones. They provide a stable, repeatable base for linear setups and multi-part machining applications.

Whether you choose round or rectangular, every Full Grip plate is engineered for precision and long-term stability, ensuring you get the most out of your zero point fixturing system.

FAQs

Are your single zero point plates compatible with other brands?

Yes. Our zero point workholding plates use standard 52 mm and 96 mm interfaces, making them compatible with most major brands, including Schunk, Lang, and Jergens-style systems.

What are the advantages of single zero point plates compared to combo plates?

Single plates are ideal for dedicated setups, smaller parts, or rotary applications where space and precision matter most. Combo plates are better suited for multi-fixture or batch production environments.

Do you provide blank versions for custom hole machining?

Yes. We offer both pre-drilled and blank zero point plates, allowing you to machine mounting holes according to your specific machine table or pallet dimensions.