-

- Single Plates, Zero Point Plates

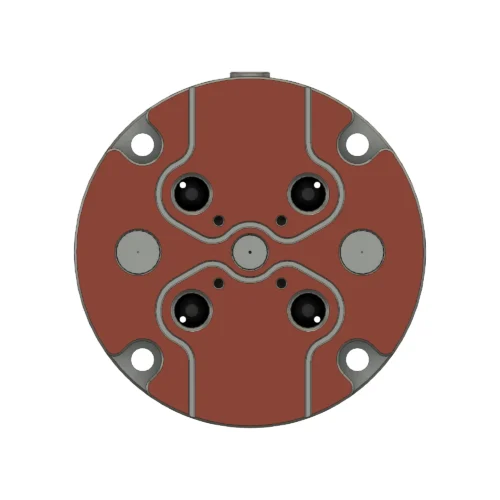

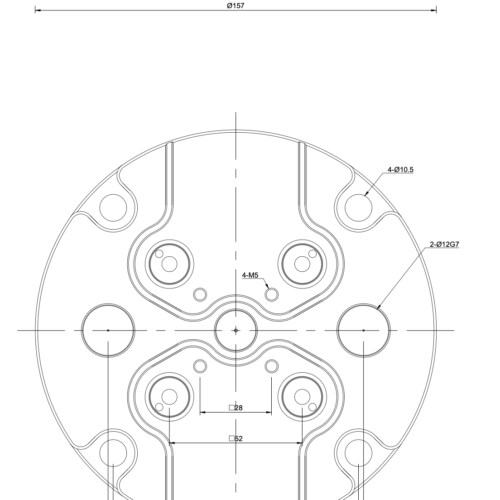

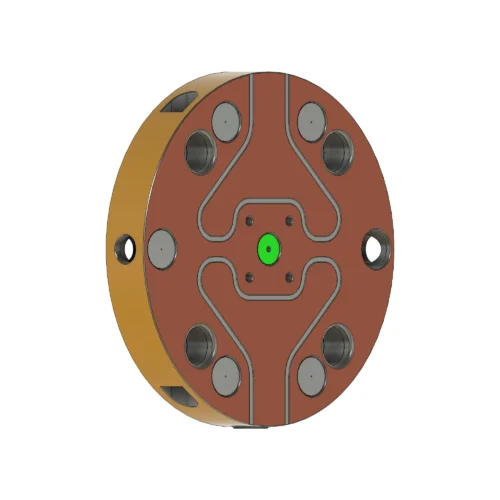

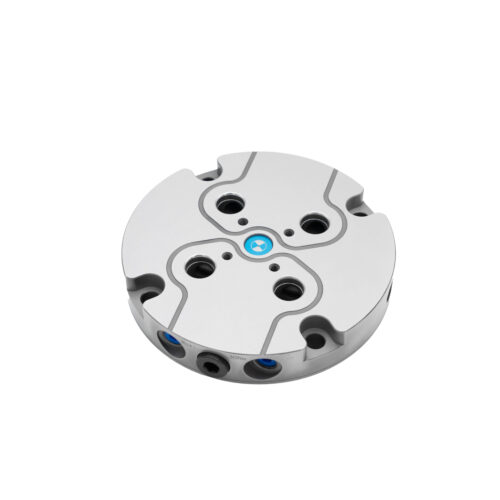

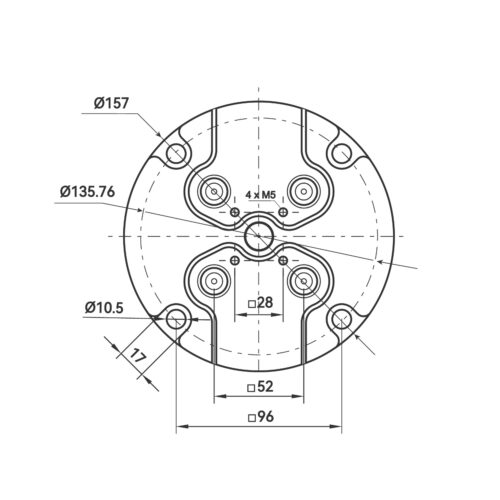

Zero Point Plate – Round – Ø157x27mm – Grid 52

- $700.00 incl. GST

- The TFG Round Zero-Point Plate (Ø157mm) is a high-precision mounting receiver engineered to provide a rock-solid foundation for System 52 (Ø16mm stud) workholding. Crafted from premium SUS440C Stainless Steel and…

- Add to cart

-

- Single Plates, Zero Point Plates

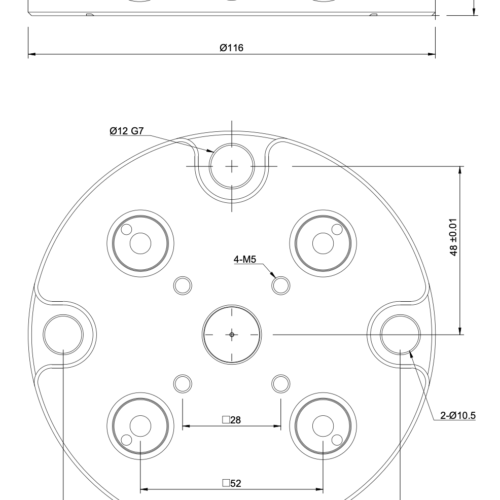

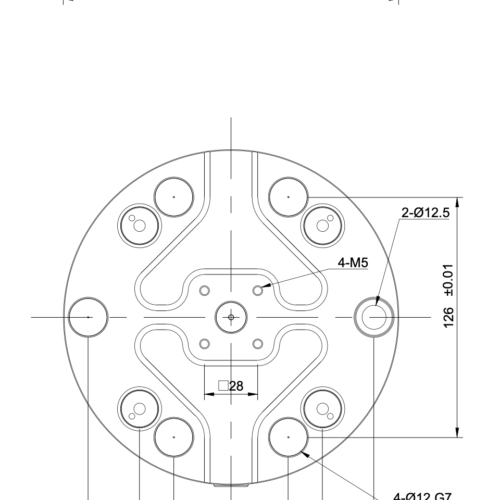

Zero Point Plate – Round – Ø116x27mm – Grid 52

- $469.00 incl. GST

- The TFG Round Zero-Point Plate (Ø116mm) is an ultra-compact, high-performance receiver engineered for precision CNC machining where space is at a premium. Designed specifically for the System 52 grid (Ø16mm…

- Add to cart

-

- Single Plates, Zero Point Plates

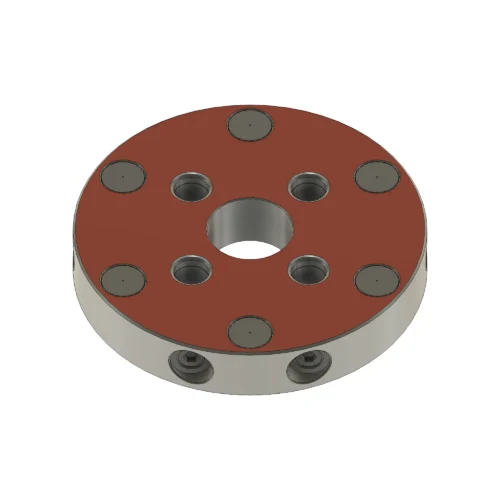

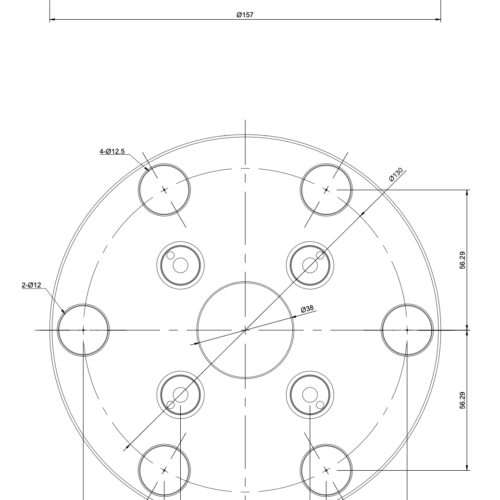

Zero Point Plate – Round – Ø157x27mm (Centre Hole) – Grid 52

- $585.00 incl. GST

- The TFG Round Zero-Point Plate (Grid 52) with Centre Hole is a high-precision, compact receiver engineered to optimize the performance of 5-axis rotary tables and smaller CNC machining centers. Designed…

- Add to cart

-

- Single Plates, Zero Point Plates

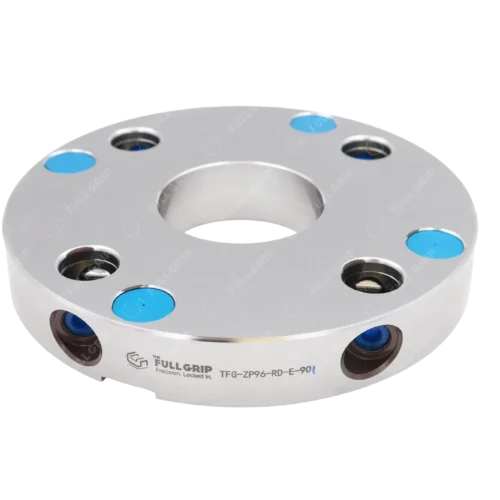

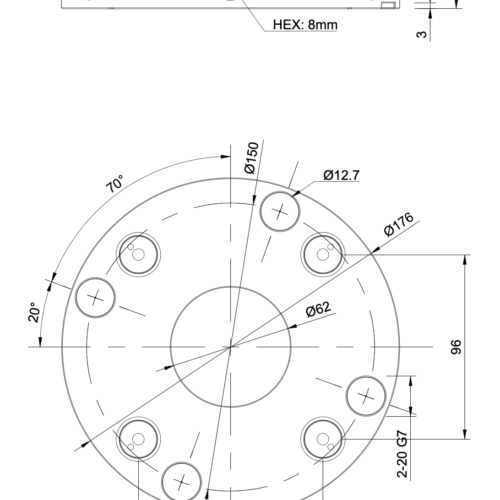

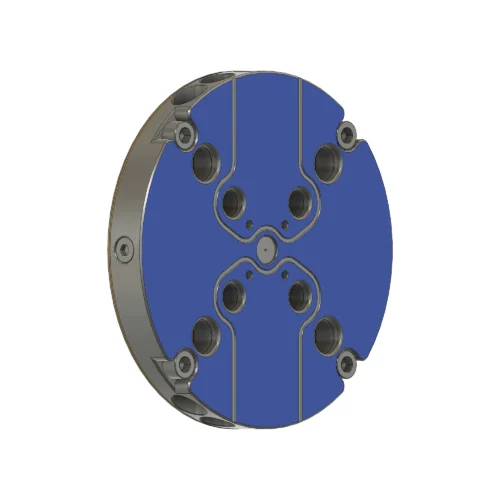

Zero-Point Plate – Round – Ø176x27mm (Centre Hole) – Grid 96

- $949.00 incl. GST

- The TFG Round Zero-Point Plate (Grid 96) with Center Hole is a versatile, high-precision receiver engineered to streamline palletized workflows in complex CNC machining. Designed for the System 96 grid…

- Add to cart

-

- Single Plates, Zero Point Plates

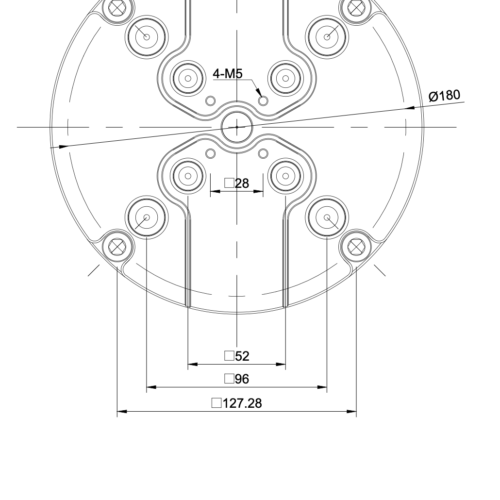

Zero-Point Plate – Round – Ø176x27mm – Grid 96

- $703.00 incl. GST

- The TFG Round Zero-Point Plate (Grid 96) is a high-performance mounting receiver engineered to provide an ultra-stable, repeatable foundation for large-scale CNC machining. Purpose-built for the System 96 grid (Ø20mm…

- Add to cart

-

- Single Plates, Zero Point Plates

Zero-Point Plate – Round – 52 / 96 Grid – 199x27mm

- $976.00 incl. GST

- The TFG Round 96 & 52 Zero Point Plate is the ultimate crossover workholding solution, engineered to unify your shop’s tooling ecosystem. This high-precision receiver features a unique dual-grid interface,…

- Add to cart

-

- Combo Plates, Single Plates, Zero Point Plates

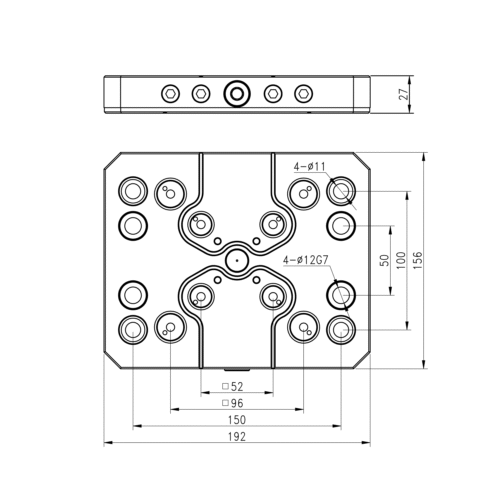

Zero-Point Combo Plate – 52 / 96 Grid – Rectangle – 192x156x27mm

- $1,080.00 incl. GST

- Modular Zero-Point Base Plate for Mixed-System Machining Dimensions Weight 192×156x27 mm 5.3 kg The Full Grip – 52 / 96 Combi Plate / Square is the perfect all-rounder for workshops…

- Add to cart

-

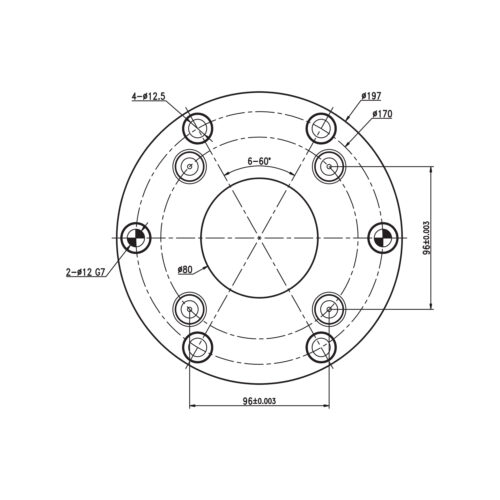

- Single Plates, System 96, Zero Point Plates

Zero-Point Plate – Round – Ø197x27mm – Grid 96

- $949.00 incl. GST

- Heavy-Duty Zero-Point Clamping Plate for Maximum Holding Power Dimensions Weight Ø197x27mm 4.8 kg Built for serious holding strength and unbeatable repeatability, The Full Grip – 96 Round Plate is a…

- Add to cart

-

- Combo Plates, Single Plates, Zero Point Plates

Zero-Point Combo Plate – 52 / 96 Grid – Rectangle – 192x156x27mm

- $1,080.00 incl. GST

- Dual-System Zero-Point Base Plate for Maximum Flexibility and Control Dimensions Weight 192×156× 27 mm 5.3kg When adaptability meets precision, you get The Full Grip – 52 / 96 Combo Plate…

- Add to cart

-

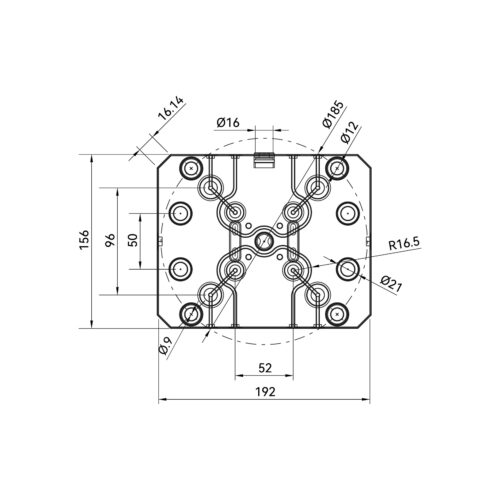

- Single Plates, System 96, Zero Point Plates

Zero-Point Plate – Rectangle – Ø192x156x27mm – Grid 96

- $700.00 incl. GST

- Heavy-Duty Zero-Point Clamping Plate for Maximum Holding Power Dimensions Weight Ø192×156x27 mm 5.4 kg From complex part machining to quick-change fixturing, The Full Grip – 96 Square Plate brings…

- Add to cart

-

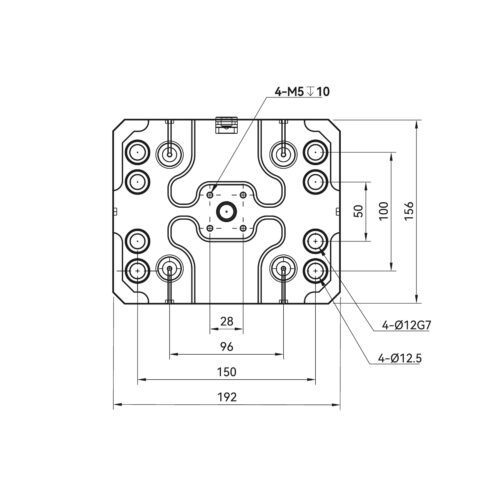

- Single Plates, System 52, Zero Point Plates

Zero-Point Plate – Round – Ø157x27mm – Grid 52

- $649.00 incl. GST

- High-Precision Zero-Point Base Plate for CNC Machining Dimensions Weight Ø157x27mm 3.8 kg When repeatability, speed, and reliability matter, the TFG 52 Single Plate delivers. Engineered for precision and built…

- Add to cart

-

- Single Plates, System 52, Zero Point Plates

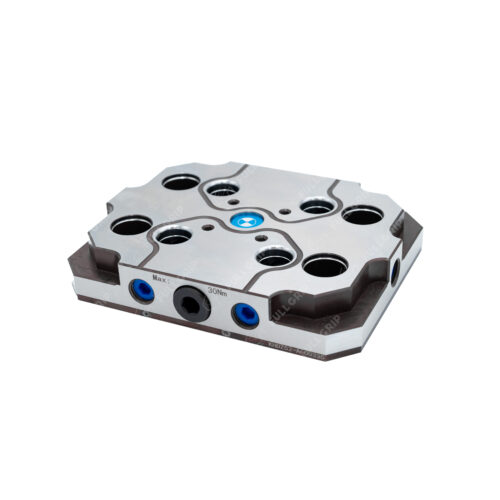

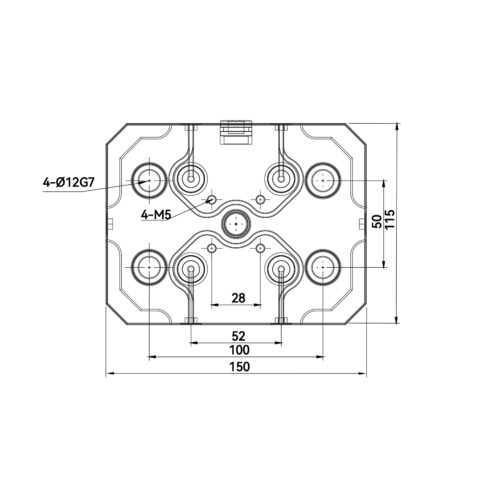

Zero-Point Plate – Rectangle – 150x116x27mm – Grid 52

- $660.00 incl. GST

- High-Precision Zero-Point Base Plate for CNC Machining Dimensions Weight 150×116x27 mm 2.9 kg When repeatability, speed, and reliability matter, the TMC 52 Single Plate delivers. Engineered for precision and built…

- Add to cart