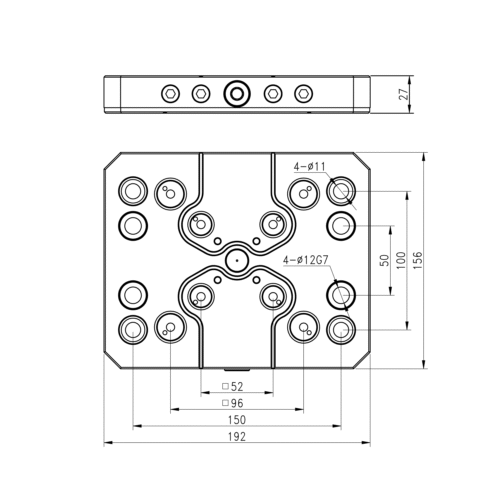

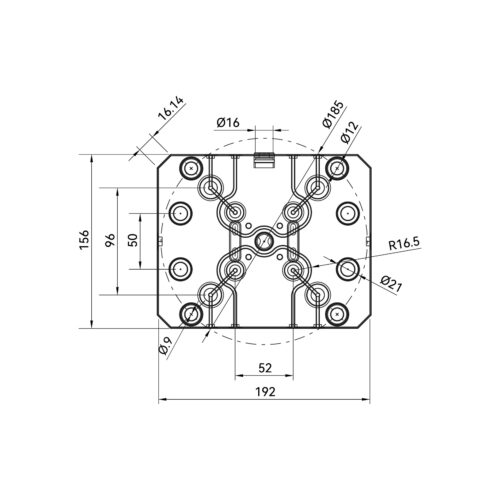

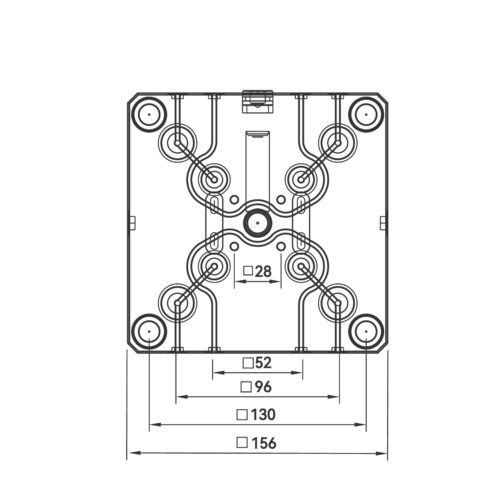

Unlike single zero point plates, which are designed for dedicated part setups, combo plates are built for versatility and throughput. By incorporating both 52 mm and 96 mm grids in one body, machinists can mount different workholding systems side by side without retooling or repositioning fixtures.

This hybrid design allows you to swap between small and large vices, or mix multiple fixture types in one setup, reducing downtime and improving workflow efficiency. For shops running multiple job sizes or mixed-batch production, combo plates are the go-to solution for speed and adaptability.

Every Full Grip combo plate is machined from premium martensitic tool steel, hardened to HRC 55–58. This ensures extreme rigidity, surface stability, and resistance to deformation, even under repeated high-clamping forces.

The hardened structure also maintains long-term flatness and precision, ensuring your plate will continue to deliver high repeatability and consistent performance through countless changeovers.

This level of compatibility gives machinists complete freedom to integrate different tooling systems while maintaining the precision of a single unified grid.

We understand that every machine table is unique. The Full Grip offers custom combo plates, whether you need specific mounting holes, altered stud spacing, or plate dimensions tailored to your setup.