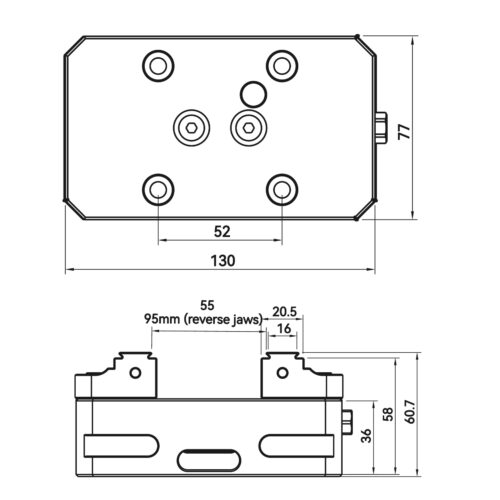

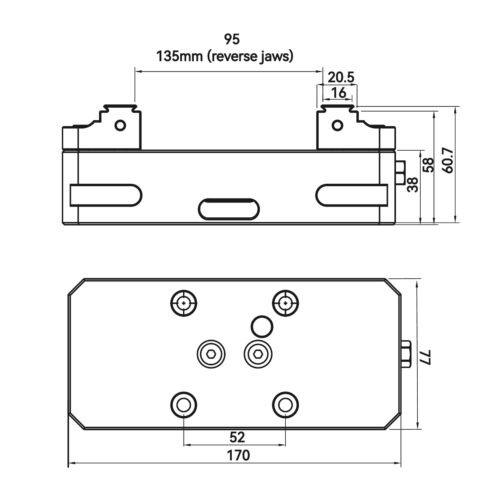

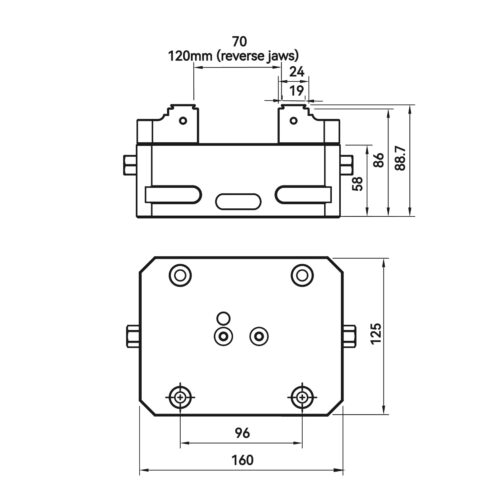

When it comes to holding parts securely and consistently, a self-centering vice is more than just a clamping tool, it’s the foundation of machining accuracy. At The Full Grip, our precision self-centering vices are designed from the ground up to deliver unbeatable repeatability (≤ 0.01 mm), even under demanding production cycles.

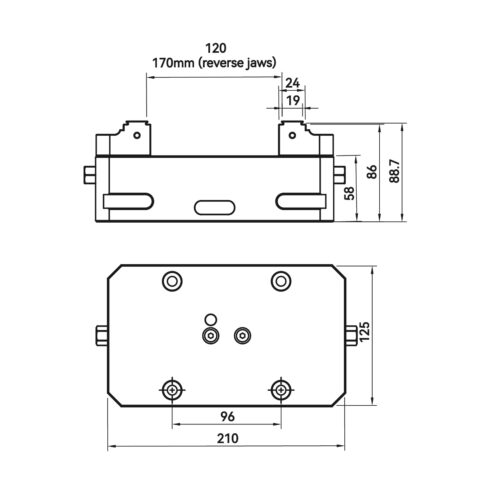

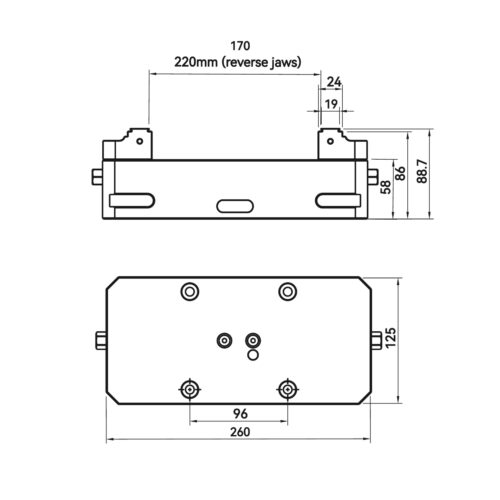

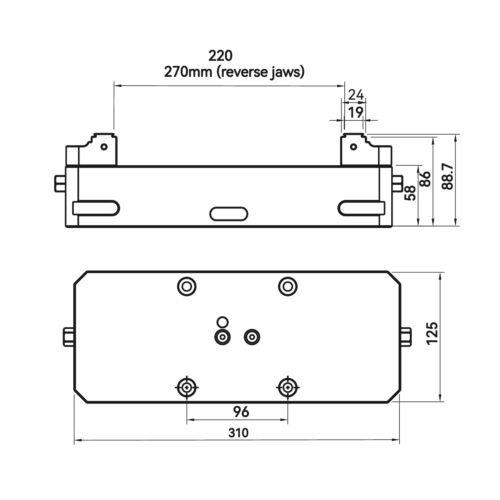

Each vice features a precision-ground body and guided slideways that keep your workpiece perfectly aligned, ensuring every operation from milling, drilling, or inspection, maintains the same centreline accuracy. The low-profile design provides maximum rigidity with minimal spindle interference, ideal for both small self-centering vices and large-scale fixtures.

A low-profile self-centering vice keeps your setup compact while maintaining exceptional grip strength. This reduced height gives machinists better tool access, reduces vibration, and improves chip clearance – critical for multi-axis and high-precision jobs.

Whether you’re running a self-centering milling vice on a vertical machining centre or a rotary table, you’ll get the same consistent performance and accuracy.

This modular approach keeps your shop flexible as your jobs evolve, ensuring every fixture you build today can adapt for tomorrow’s projects.

We understand that precise planning saves time and reduces waste. That’s why we offer free 3D CAD models of our self-centering machine vices, so you can test-fit our products directly in your CAD environment. Check clearances, simulate setups, and confirm fit before committing to purchase.

This feature has become invaluable for machinists and engineers designing custom fixtures or verifying compatibility with complex setups.

Backed by decades of machining knowledge, The Full Grip is committed to delivering precision workholding systems that keep your spindle running efficiently. Whether you’re upgrading from a standard centering vise or expanding into modular fixturing, our precision self-centering vices give you repeatability, strength, and scalability you can rely on.

We don’t just sell vices; we help shops machine smarter and faster through innovation, modularity, and proven accuracy.