L Plates are more than just a mounting accessory, they’re a gateway to greater flexibility and productivity. Designed for precision alignment and rigid support, our L Plates make it easy to fixture parts vertically or at multiple angles, unlocking new machining possibilities on 3-axis and 4-axis CNC machines.

When paired with the right components, they transform standard setups into modular, multi-angle systems that cut down on changeovers and maximise spindle uptime.

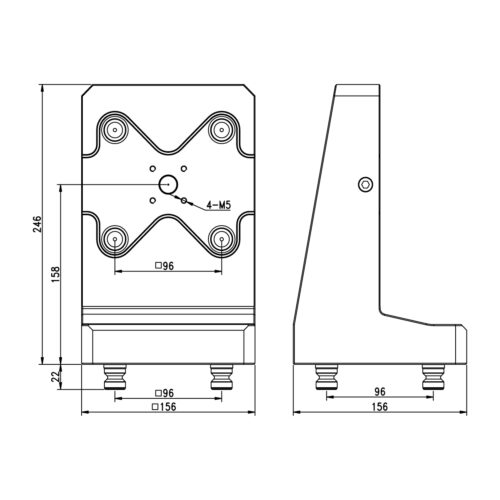

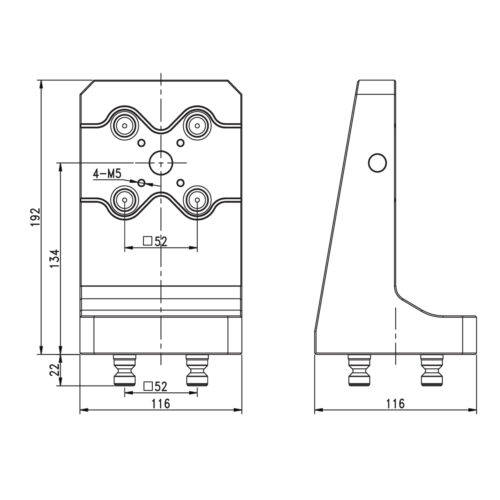

Every Full Grip L Plate is precision-machined for seamless compatibility with Grid 52 and Grid 96 zero point systems, ensuring you can mix and match with your existing workholding setup.

No matter your table size or machine configuration, our grid-standard L Plates provide the foundation for consistent, repeatable, and highly adaptable setups.

L Plates give machinists the ability to clamp components in multiple orientations, ideal for 3-axis and 4-axis machining.

By allowing the workpiece to be fixed vertically or at precise angles, you can machine multiple faces in a single setup, improving both throughput and accuracy.

This flexibility reduces the need for multiple fixtures or re-clamping operations, saving valuable time while maintaining positional accuracy throughout production runs.

The true potential of L Plates shines when combined with Zero Point Plates and Self-Centering Vices. Together, these components allow you to approach your workpiece from virtually any direction, giving you 5-axis-like accessibility… even on 4-axis machines.

By integrating L Plates into your modular system, you can achieve full workpiece access, faster part changeovers, and more efficient machining strategies, all without needing to invest in a dedicated 5-axis machine.

Manufactured from hardened tool steel, our L Plates are designed for durability, strength, and long-term accuracy. Each plate undergoes precision grinding and inspection to ensure perfect perpendicularity and surface flatness – critical factors for high-accuracy machining and repeatable results.

When paired with your existing modular system, The Full Grip L Plates turn every fixture setup into a precision platform capable of handling any job, big or small.