Case Study

Cobalt CNC maximises productivity with The Full Grip Zero Point System

Project

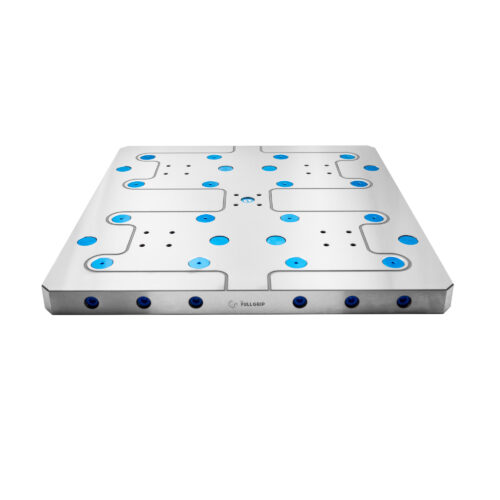

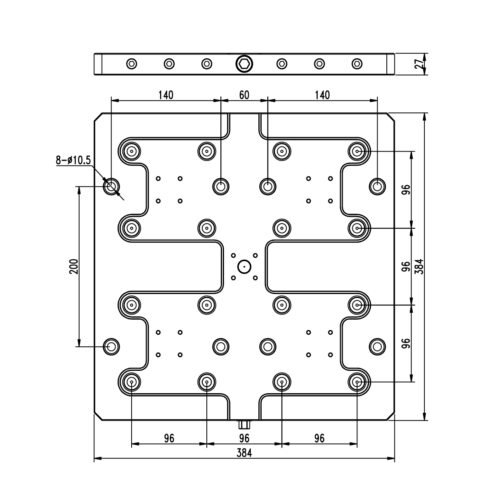

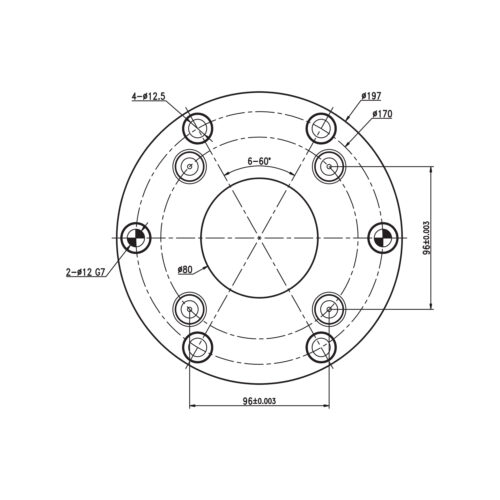

Upgrading workholding efficiency and durability with hardened steel combo zero point plates

Background

Cobalt CNC is a high-mix, quick-turnaround job shop specialising in precision steel components. Their daily workflow demands rapid fixture changes and reliable repeatability.

For years, the team used aluminium zero point plates from 5th Axis alongside Dianjin vices. However, as their workload shifted heavily toward steel machining, the limitations of aluminium plates became increasingly apparent.

That’s when Cobalt CNC made the switch to The Full Grip Zero Point System – starting with a 197 × 197 mm Zero Point Plate and later expanding to include 384 × 384 mm Quad Plates and 90° L-Plate fixture bases.

Challenge

In Cobalt CNC’s fast-paced environment, every minute spent on setup is a minute lost in production.

The team faced persistent issues with their aluminium plates:

⚠️ Dents and scratches from heavy steel work

⚠️ Frequent stoning and surface maintenance

⚠️ Slow job changes due to multi-screw tightening systems

⚠️ Excessive downtime for plate cleaning between setups

For a shop performing multiple changeovers each day, these small inefficiencies added up to significant lost time and wear.

The Full Grip Solution

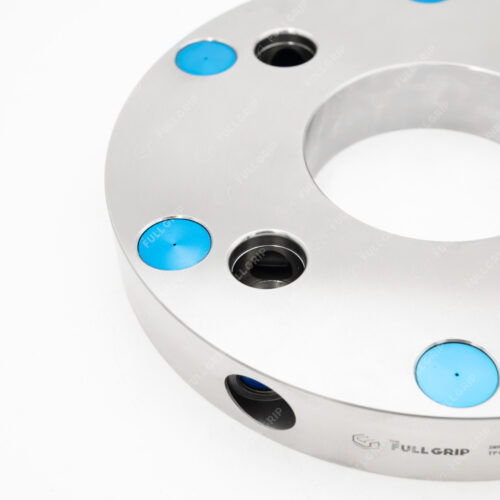

Cobalt CNC upgraded to The Full Grip’s hardened steel Zero Point Plates, precision surface-ground and engineered for heavy-duty use.

The result: a simplified, more durable system that drastically cut setup time and maintenance.

Key advantages realised:

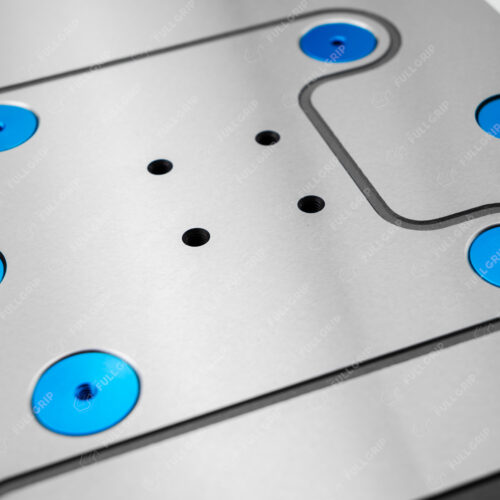

Superior durability

“We haven’t had any dents or scratches since switching. They’re hardened steel and surface ground - no stoning needed.”

Faster changeovers

“The single-screw tightening saves a huge amount of time. With the old system, we had three screws per plate. Now it’s one screw and we’re done.”

Cleaner workflow

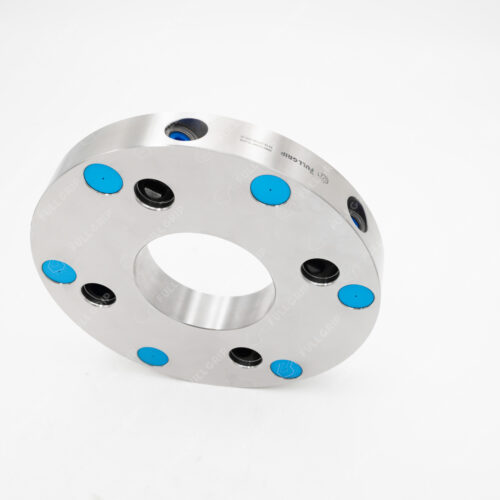

“Having one big plate instead of a few smaller ones means less mess between jobs. The coolant just blows it off - a quick air blast and we keep going.”

Optimised for quick-turn work

The system’s design perfectly suits Cobalt CNC’s business model, which focuses on short runs, tight turnarounds, and high accuracy across multiple part types.

Results

Since adopting The Full Grip Zero Point System, Cobalt CNC reports measurable efficiency improvements across the board:

😃 Significant reduction in setup and changeover times

😃 Longer fixture life with minimal maintenance

😃 Higher consistency and reduced risk of part movement

😃 Smoother daily operation – fewer interruptions, more cutting time

For Cobalt CNC, the investment quickly proved its value:

“We change our workholding multiple times a day, and these plates have saved us a huge amount of time compared to other zero point systems. The one-screw design and full steel construction make all the difference.”

Conclusion

The Full Grip Zero Point System has become an essential part of Cobalt CNC’s workflow. By combining durability, speed, and precision, it enables the shop to maintain high productivity without compromising quality.

As Cobalt CNC expands its setup with additional Quad and L-Plate fixtures, their move to The Full Grip system continues to pay off — proof that the right workholding foundation transforms not just setups, but the entire machining process.